The Airbus A380 is the world’s largest passenger airliner, a wide-body aircraft manufactured by Airbus. The first prototype was unveiled in Toulouse on 18 January 2005, with its first flight on 27 April 2005. The full-length double-deck aircraft has a typical seating capacity of 525, though it is certified for up to 853 passengers. I simply love Airbus planes – particularly A350 & A380 and has been very closely following since the project inception in 2000s to demo flights in 2005 / 2006 when it visited Shanghai among other cities in the world to first flight between Singapore – Sydney in 2007 and till now. I also closley followed the Airbus factories in Hamburg & Tianjin. Im very sad that production of A380 would cease in 2021

How is the AIRBUS A380 less noisy ?

- Thanks to its modern engines and aerodynamic improvements, Lufthansa’s A380s produce half the noise of the Boeing 747-200 while carrying 160 more passengers

- In 2012, the A380 received an award from the Noise Abatement Society

- London Heathrow is a key destination for the A380

- The aircraft is below the QC/2 departure and QC/0.5 arrival noise limits under the Quota Count system set by the airport

- Field measurements suggest the approach quota allocation for the A380 may be overly generous compared to the older Boeing 747, but still quieter

- Rolls-Royce is supporting the CAA in understanding the relatively high A380/Trent 900 monitored noise levels

- Heathrow’s landing charges having a noise component, the A380 is cheaper to land there than a Boeing 777-200 and -300 and it saves $4,300 to $5,200 per landing, or $15.3M to $18.8M of present value over 15 years

- Tokyo Narita has a similar noise charge

- Sufficient braking capacity allowed for thrust reversers to be installed on only the inboard engines

- The outboard engines lack them, reducing the amount of debris stirred up during landing

- The reversers are electrically actuated to save weight, and for better reliability than pneumatic or hydraulic equivalents

AIRBUS A380 ENGINE

OPTION 1

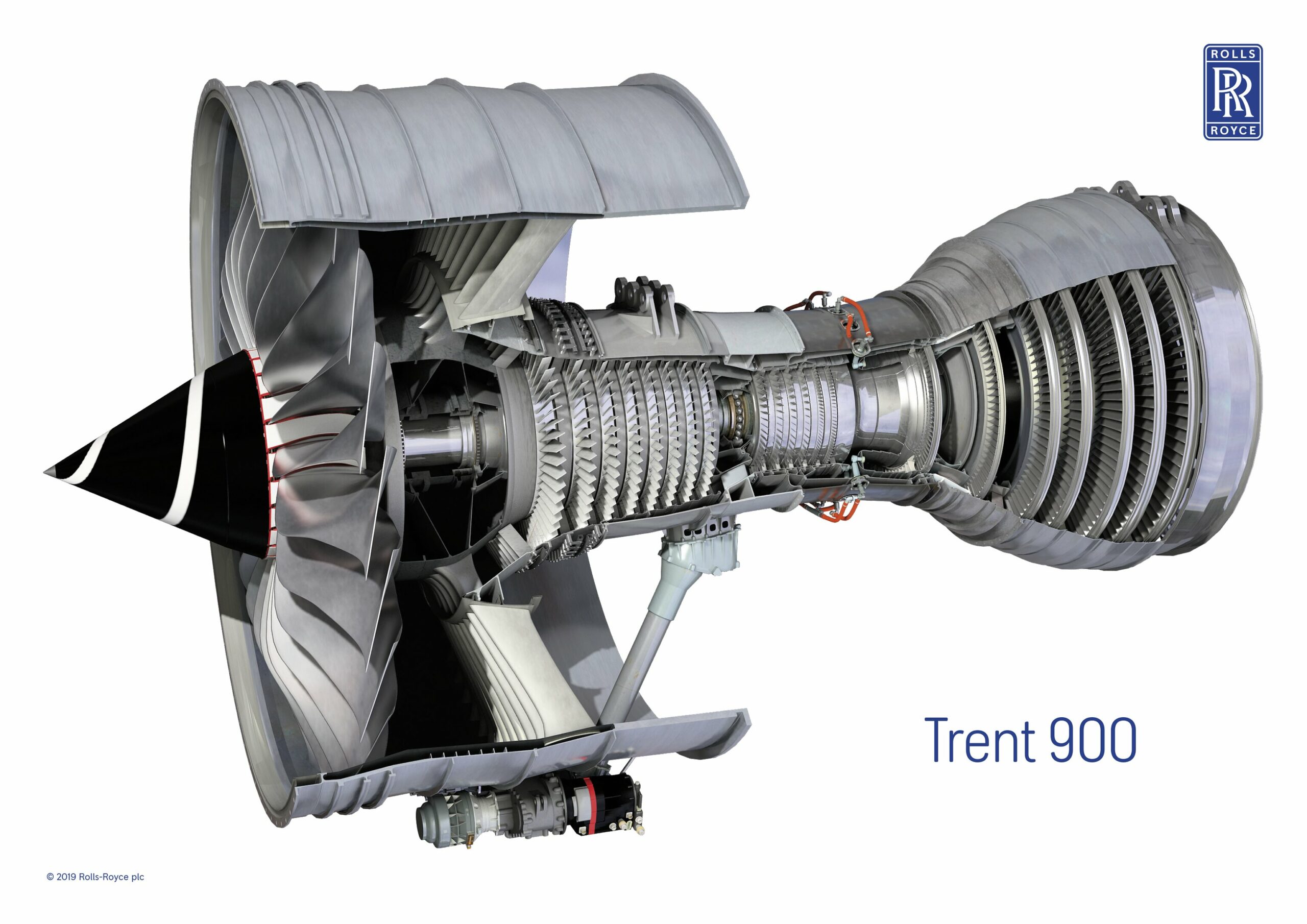

Rolls-Royce Trent 900

The Rolls-Royce Trent 900 is a high bypass turbofan produced by Rolls-Royce plc to power the Airbus A380, competing with the Engine Alliance GP7000

It is one of the powerplant options available for the Airbus A380, along with the Engine Alliance GP7000

- Type : Turbofan

- First run : 18 March 2003

- Program cost : $450 million

General characteristics

- Type : Three-shaft high bypass turbofan engine

- Length : 5478 mm (215.7 in) tip of spinner minus rubber tip to Tail Bearing Housing Plug Mount Flange

- Diameter : 2950 mm (116 in) fan

- Dry weight : 6246 kg (13770 lb)

Components

- Compressor : single stage LP (fan), 8-stage IP axial compressor (IPC), 6-stage HP axial compressor (HPC)

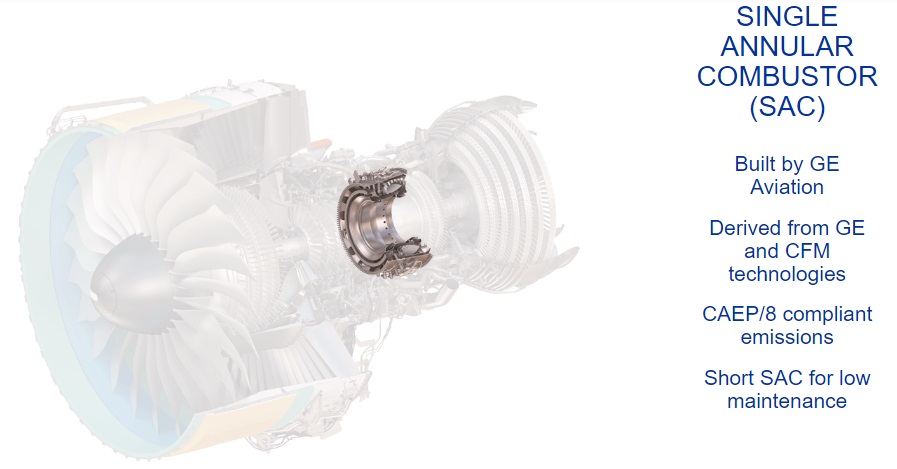

- Combustors : Single annular combustor

- Turbine : single stage HP turbine (HPT), single stage IP turbine (IPT), 5-stage LP turbine (LPT)

Performance

- Maximum thrust : 334.29 to 374.09 kN (75,152 to 84,098 lbf)

- Overall pressure ratio : 37–39

- Bypass ratio : 8.5 – 8.7

- Air mass flow : 2655–2745 lb (1204–1245 kg)/sec

- Thrust-to-weight ratio : 5.46 – 6.11

- The Rolls-Royce Trent 900 is a high bypass turbofan produced by Rolls-Royce plc to power the Airbus A380, competing with the Engine Alliance GP7000

- Initially proposed for the Boeing 747-500/600X in July 1996, this first application was later abandoned but it was offered for the A3XX, launched as the A380 in December 2000

- It first ran on 18 March 2003, made its maiden flight on 17 May 2004 on an A340 testbed, and was certified by the EASA on 29 October 2004

- Producing up to 374 kN (84,000 lbf), the Trent 900 has the three shaft architecture of the Rolls-Royce Trent family with a 2.95 m (116 in) fan

- It has a 8.5-8.7:1 bypass ratio and a 37–39:1 overall pressure ratio

- The A3XX was launched as the A380 on 19 December 2000

- It was then selected by Singapore Airlines and Virgin Atlantic over the competing GP7200

- The Trent 900 ran for the first time on 18 March 2003, achieving its certification thrust of 81,000 lbf (360 kN) on 2 April and attaining 88,000 lbf (390 kN) a week later, with growth room to 94,000 lbf (420 kN)

- Its 300 cm (118 in) fan comes from the Trent 8104 demonstrator, and a contra-rotating HP spool is used for the first time, for up to 2% better efficiency

- The Trent 900 made its maiden flight on 17 May 2004 on Airbus’ A340-300 testbed, replacing the port inner CFM56 engine

- Its final certification was granted by the EASA on 29 October 2004 and the FAA on 4 December 2006

- After a twelve-month suspension caused by delays to the A380, Rolls-Royce announced in October 2007 that production of the Trent 900 had been restarted

- On 27 September 2007, British Airways announced the selection of the Trent 900 to power 12 A380 aircraft helping to take the engine’s share of the A380 engine market to 52% at the end of February 2009

Consistently the most reliable and durable A380 engine

- The lowest lifetime fuel burn on A380

- Lowest lifecycle operating cost for the Airbus A380

- Committed to continuously improving our engines with low-risk new technology from future generations, something the Trent 900 has benefitted from significantly, delivering fuel burn improvements since EIS of up to 1.6%

- The Trent 900 is the fourth member of the Trent family and includes the latest technology proven to reduce noise and weight whilst increasing efficiency

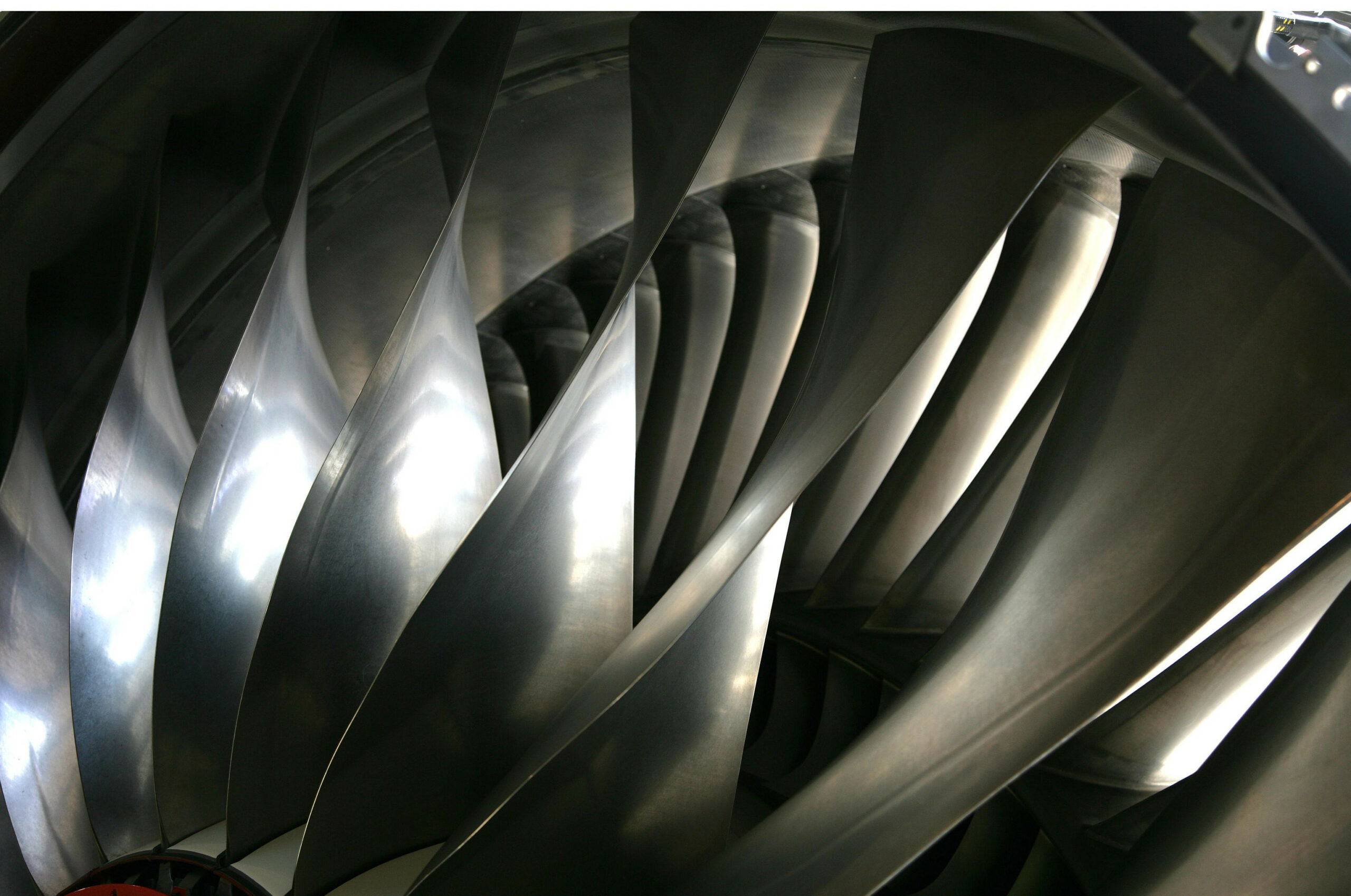

- For example, the engine’s 24 fan blades are to a new swept design that reduces the effect of shock waves as the tip of the fan rotates supersonically

- The fan containment system is also the first to be manufactured from titanium rather than Kevlar, and at the core of the engine the high-pressure shaft rotates in the opposite direction to the other two shafts for greater fuel efficiency

-

Fuel burn improvements since EIS : 1.6%

116”

116”

-

Diameter of advanced swept fan

- Continuous technical improvements have been incorporated into the engine

- Current engines are to the ‘EP3’ build standard, incorporating three continuous improvement steps

- 116-inch diameter advanced swept fan

- Advanced 3D compressor & turbine aerodynamic designs

- Tiled low-NOx combustor

- Contra-rotating HP system

- Engine Health Monitoring

- The only A380 engine that can be loaded into a 747 freighter without disassembly

Rolls-Royce Trent 900 : Design

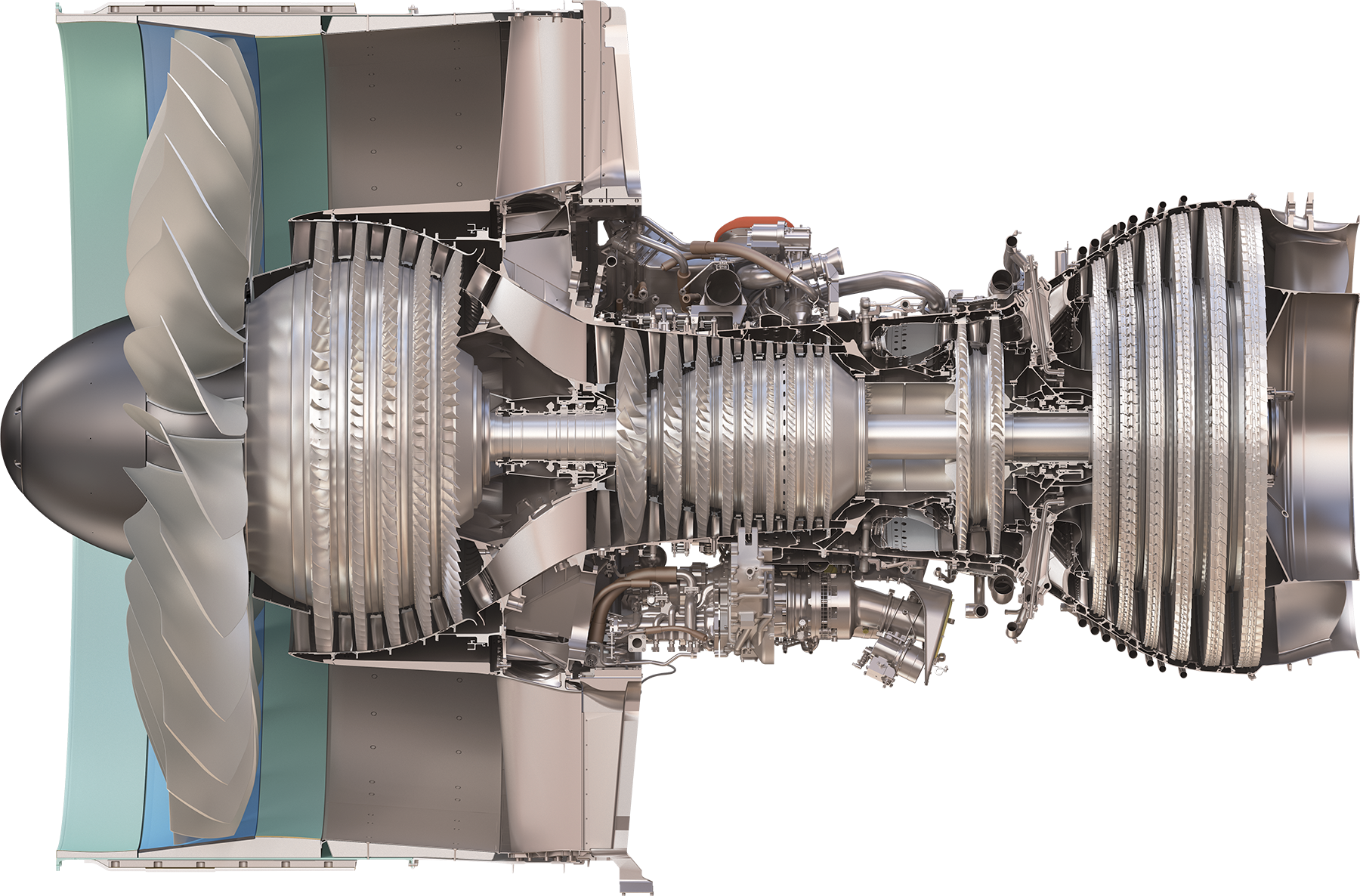

- The Trent 900 is an axial flow, high bypass turbofan with the three coaxial shafts of the Rolls-Royce Trent family

- The 2.95 m (116 in) fan with swept blades is driven by a 5-stage LP turbine, the 8-stage IP compressor and the 6-stage HP compressor are both powered by a single stage turbine, with the HP spool rotating in the opposite direction of the others

- It has a single annular combustor and is controlled by an EEC

- It is certified for thrusts between 334.29 to 374.09 kN (75152 to 84098 lbf)

- Its swept-back fan is inherited from the Trent 8104 demonstrator and a contra-rotating HP spool is used for the first time

- It features a scaled-down Trent 800 core

- It can be transported on a Boeing 747 freighter whole, the only A380 engine capable of

- The swept-back fan is 15% lighter than previous wide-chord blades

- Rolls-Royce has seven risk and revenue sharing partners on the Trent 900: Industria de Turbo Propulsores (low-pressure turbine), Hamilton Sundstrand (electronic engine controls), Avio S.p.A. (gearbox module), Marubeni Corporation (engine components), Volvo Aero (intermediate compressor case), Goodrich Corporation (fan casings and sensors) and Honeywell (pneumatic systems)

- In addition, Samsung Techwin, Kawasaki Heavy Industries and Ishikawajima-Harima Heavy Industries (IHI) are programme associates

- The Trent 900 will be the first Trent engine fitted with the advanced Engine Health Monitoring (EHM) system based on QUICK Technology

Co-operation & Competition at the same time !

- Whereas most members of the Trent family are controlled by FADECs from Goodrich, engine controllers on the Trent 900 are provided by Hamilton Sundstrand, a United Technologies (UTC) company, the parent of Pratt & Whitney, the co-producer of the Engine Alliance GP7000 along with GE Aircraft Engines, the competing A380 powerplant

- This cooperation among competitors is prevalent in the aircraft market as it provides for risk sharing and diversity in source countries, which may be a factor in an airline’s choices

AIRBUS A380 ENGINE

OPTION 2

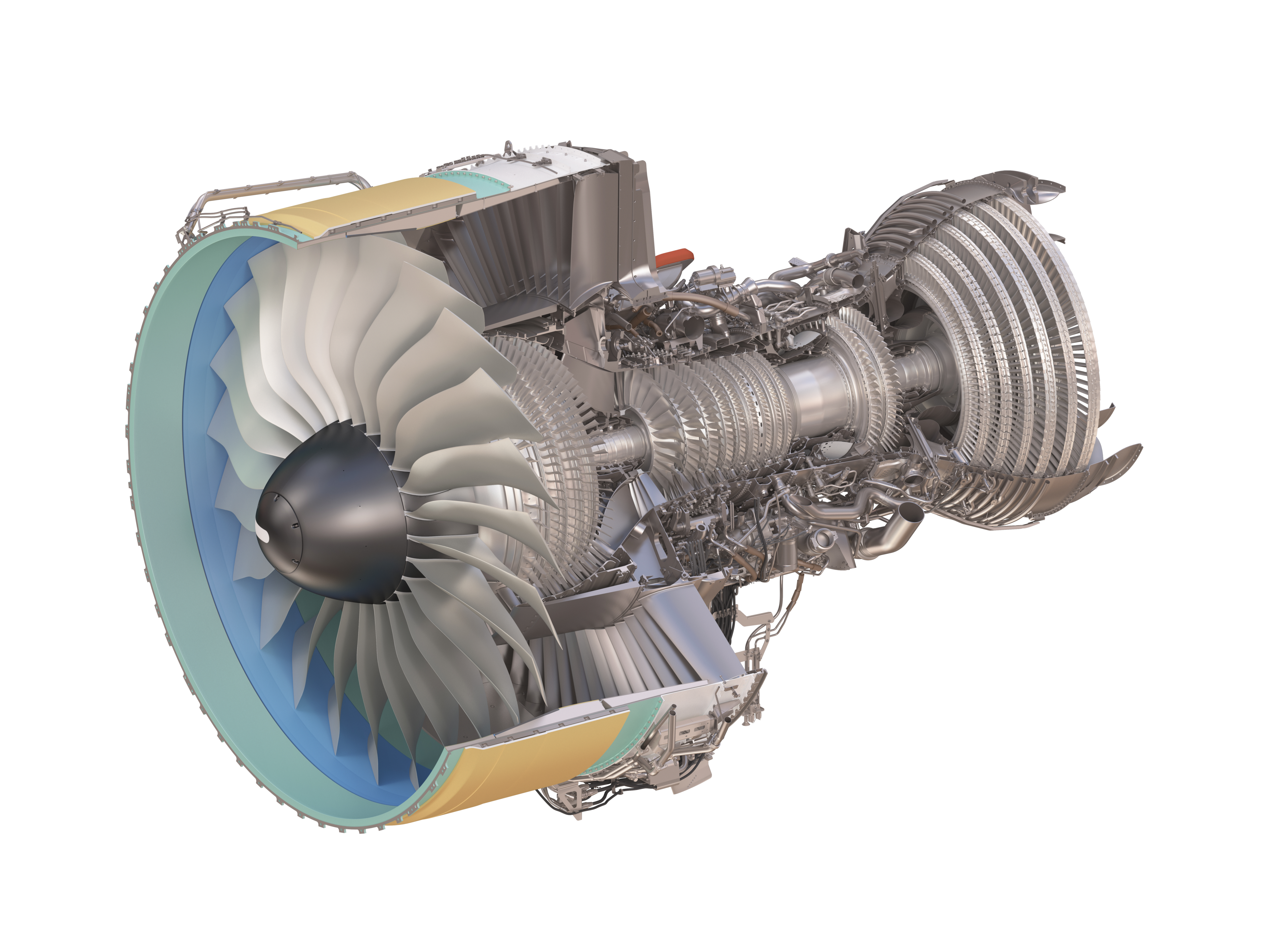

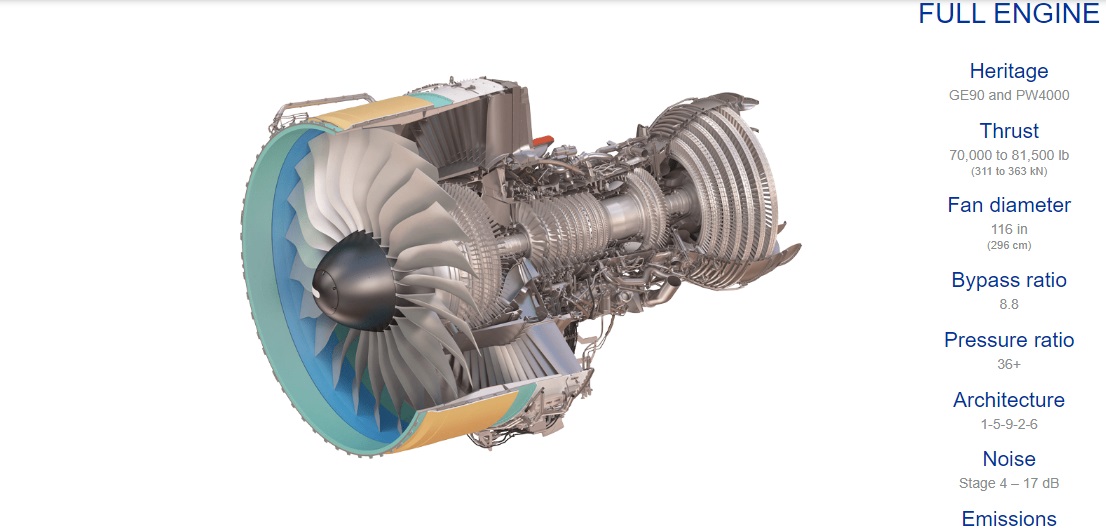

Engine Alliance GP7200

The Engine Alliance GP7200 is a turbofan jet engine manufactured by Engine Alliance, a joint venture between General Electric and Pratt & Whitney

It is one of the powerplant options available for the Airbus A380, along with the Rolls-Royce Trent 900

Emirates owns by far the lion’s share of the fleet, with well over half of the A380s flying. Air France, Etihad Airways, Korean Air and Qatar Airways also equip their A380s with the GP7200

ETIHAD (Customer Since December : 2014)

ETIHAD (Customer Since December : 2014) QATAR (Customer Since October, 2014)

QATAR (Customer Since October, 2014) KOREAN AIR (Customer Since June, 2011)

KOREAN AIR (Customer Since June, 2011) AIR FRANCE (Customer Since November, 2009)

AIR FRANCE (Customer Since November, 2009) EMIRATES (Customer Since August, 2008)

EMIRATES (Customer Since August, 2008)Up to $5.5 Million in Passenger Revenue

GP7200 delivers a payload-range advantage worth up to $5.5 million in annual passenger revenue for each A380.

Up to $500000 a year fuel savings

The most fuel efficient engine for the A380, the GP7200 minimizes expenses, resulting in up to $500,000 in annual fuel savings per aircraft.

The A380’s Most Reliable Engine

The GP7200 has logged the most reliable track record since entry into service. Clearly, the engine built for longer, more productive service

Quietest, Greenest Engine for the A380

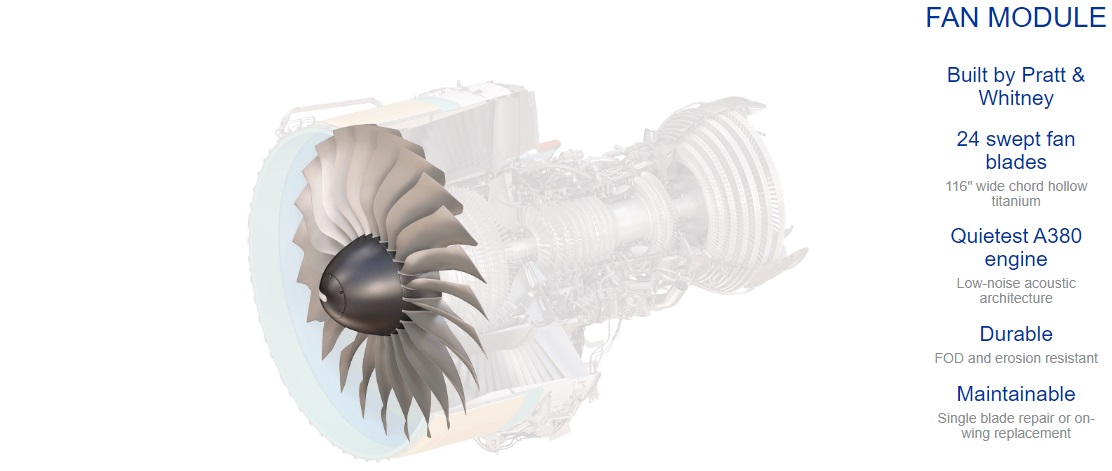

- The GP7200 delivers a whisper-quiet flying experience at 17.6 dB under Stage 4 and emissions under CAEP/8

- A380 will be noticeably quieter at 0.8 dB better than the competing engine — and save the environment 1900 metric tonnes of CO2 every year

The A380 features an 8200 nautical-mile range (15200 km), enabling it to service some of the longest routes in commercial aviation

Approaching the speed of sound

With a cruise speed of .85 Mach and a top speed of 634 mph, the A380 ranks among the top five fastest airliners

Powerfully economical

A fuel capacity of nearly 82000 gallons, a fuel consumption rate of 10 g/nm and space for up to 853 passengers makes the A380 more fuel efficient per passenger than an average economy car

What are the engine options used in AIRBUS A380 ?

Engine Alliance GP7200 engine waiting for installation

Engine Alliance GP7200 engine waiting for installation- The A380 is offered with the Rolls-Royce Trent 900 (A380-841/-842) or the Engine Alliance GP7000 (A380-861) turbofan engines

- The Trent 900 is a combination of the 3 m (118 in) fan and scaled IP compressor of the 777-200X/300X Trent 8104 technology demonstrator derived from the Boeing 777’s Trent 800, and the Airbus A340-500/600’s Trent 500 core

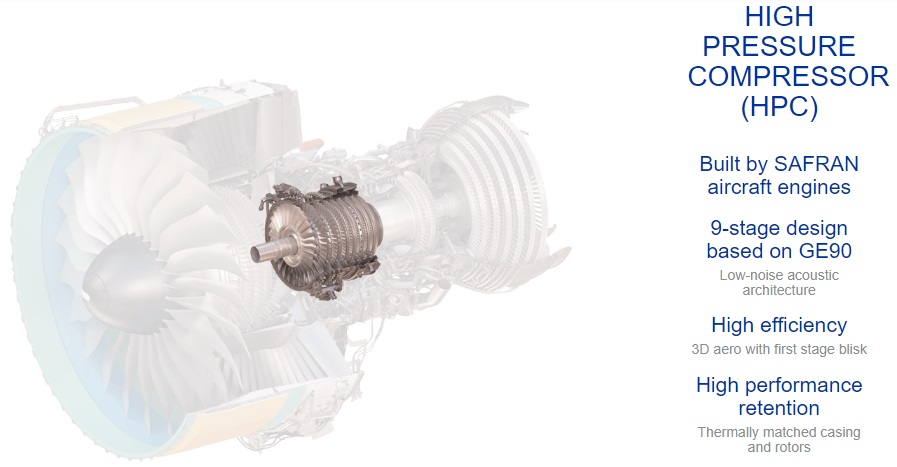

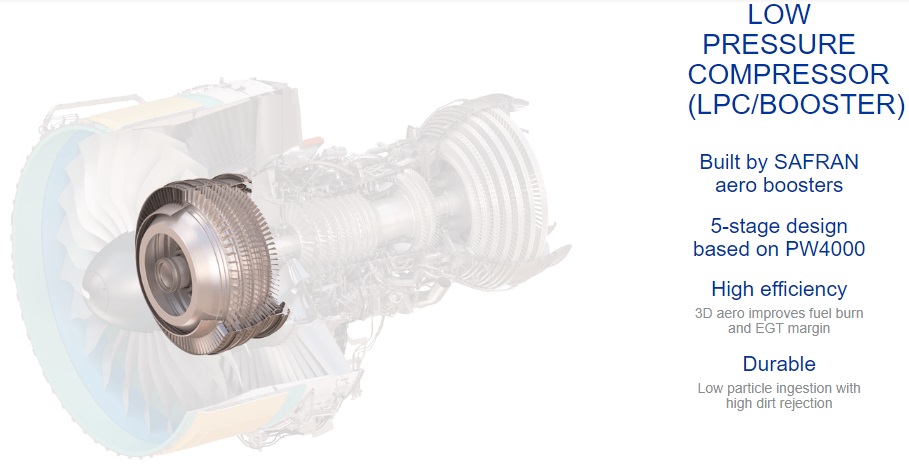

- The GP7200 HP core technology is derived from GE’s GE90 and its LP sections are based on the PW4000 expertise

Engine Alliance GP7270 : Specifications

General characteristics

- Type : two-spool high-bypass turbofan engine

- Length : 4.92 m (16.1 ft; 194 in) spinner to flange

- Diameter : 3.16 m (10.4 ft ; 124 in), fan 2.96 m (9.7 ft ; 117 in)

- Dry weight : 6712 kg (14797 lb)

Components

- Compressor :

- 24 swept wide-chord hollow titanium fan blades

- 8.8:1 by-pass ratio

- Five-stage low-pressure axial compressor

- Nine-stage high-pressure axial compressor

- Combustors : low-emissions single annular combustor

- Turbine :

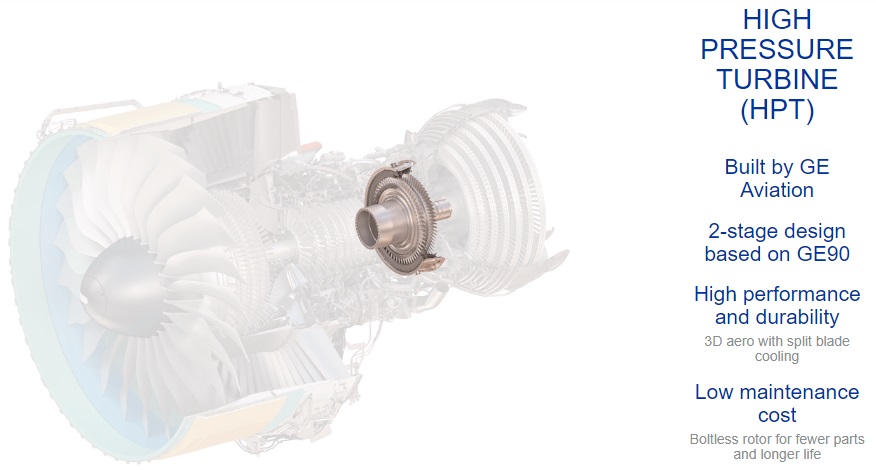

- Two-stage high pressure turbine

- Boltless architecture

- Single crystal blades

- Split blade cooling and thermal barrier coatings

- Axial flow

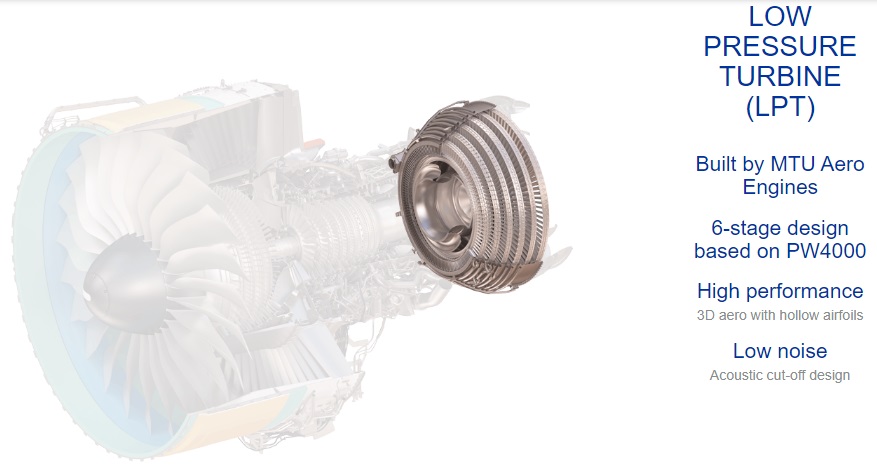

- Six-stage low-pressure axial flow

Performance

- Maximum thrust : 36980 kgf, 363 kN, 81,500 lbf

- Overall pressure ratio : 43.9

- Air mass flow : 900 to 1,200 kg/s (2,000 to 2,600 lb/s)

- Thrust-to-weight ratio : 5.197 (assuming 13400 lbf weight of engine and 70000 lbf of thrust)

- Originally intended to power Boeing Commercial Airplanes’ cancelled 747-500X/-600X, the engine has since been pushed for Airbus’ A380-800 superjumbo

- It is built around an 0.72 scale of the GE90-110B/115B core and contains a Pratt & Whitney fan and low-pressure system design

- The competing Rolls-Royce Trent 900 was named as the lead engine for the then-named A3XX in 1996 and was initially selected by almost all A380 customers

- However the GE/PW engine increased its share of the A380 engine market to the point where as of September 2007 it will power 47% of the super-jumbo fleet

- This disparity in sales was resolved in a single transaction, with Emirates’ order of 55 GP7000-powered A380-800s, comprising over one quarter of A380 sales (as of September 2007)

- Emirates has traditionally been a Rolls-Royce customer

- A380 aircraft powered by the GP7000s will have A380-86X model numbers as 6 is the code for Engine Alliance engines

- The engine powers an estimated 60% of Airbus A380 in service as reported in 2017

- Ground testing of the engine began in April 2004 and was first flight tested as the number two engine on GE’s 747 flying testbed over Victorville, CA in December 2004

- The American Federal Aviation Administration certified the engine for commercial operation on January 4, 2006

- The engine was ground run for the first time on an A380 on August 14, 2006, in Toulouse

- On August 25, 2006, the same aircraft, A380-861 test aircraft (MSN 009), made the first flight of an Engine Alliance powered A380

- The flight began and ended at Toulouse and lasted about four hours. Tests were performed on the engines’ flight envelope, cruise speed, and handling

- A day earlier, the same aircraft performed rejected takeoff tests on the engines

- The Engine Alliance offered the GP7200 for the Airbus A380 passenger and freighter configurations

- The GP7270 is rated at 74,735 lbf (332.44 kN) of thrust whilst the GP7277 is rated at 80,290 lbf (357.1 kN)

- The engine is offered with two ratings appropriate for the various A380 configurations and take-off weights: GP7270 for the 560 tonne variant, and GP7277 for the 590 tonne A380-800 freighter (which was subsequently cancelled by Airbus)

- In mid-2011 an upgrade was announced which will lead to a cut in weight for each engine by 23 kg (51 lb)

- The new components come from Volvo Aero

- MTU Aero Engines is a major partner of the programme, with 22.5% share

- The German company produces the high-pressure turbine, the low-pressure turbine and the turbine center frame

- Safran with 17.5% designs and produces the low-pressure compressor

- MDS Aero Support Corporation, a Canadian company, is working hand in hand with MTU to develop next generation test beds

- MDS in joint cooperation is building the facility to test the next version of this engine in France